Our Experience

The operation of Wind Turbines demands extremely close tolerances, precision and surface finish in the gearing components, along with high accuracy in the setting of bearing clearances.

Our Experience

The operation of Wind Turbines demands extremely close tolerances, precision and surface finish in the gearing components, along with high accuracy in the setting of bearing clearances.

Our Proven 4 Step Process

Our Proven 4 Step Process

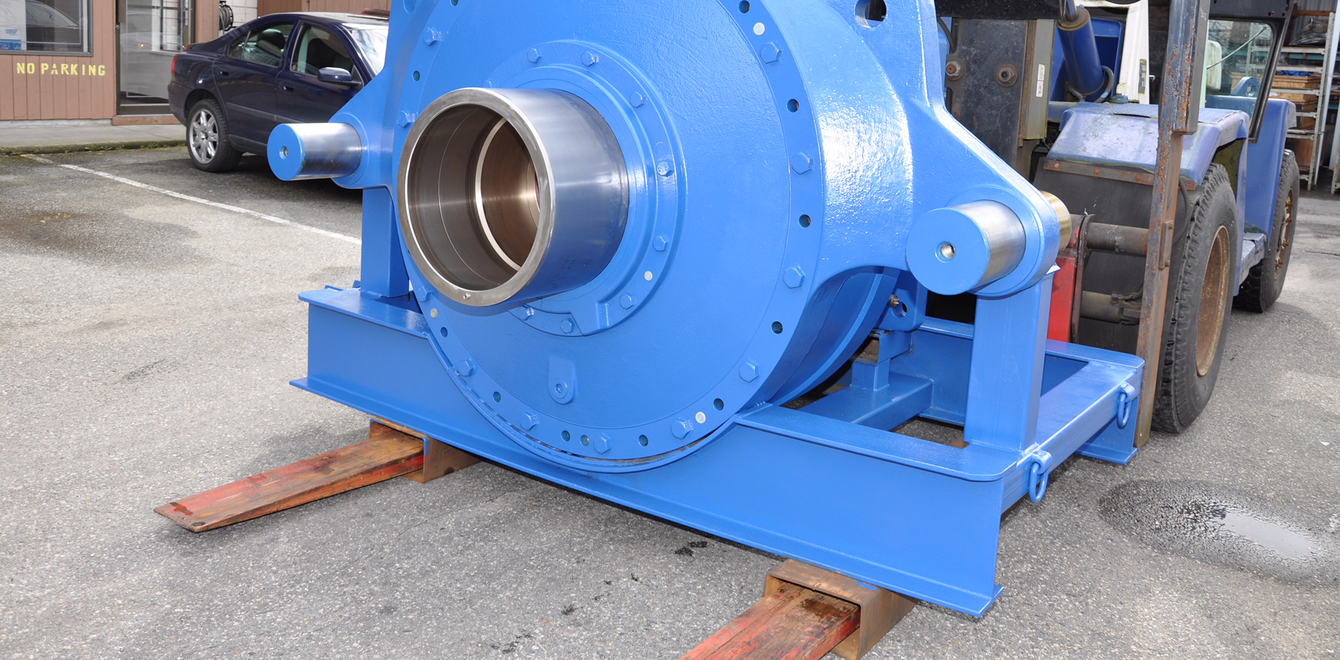

Precision Rebuild

United Gear has developed a proven method of refurbishing housing bearing bores and has refined the gear tooth geometry to assure the optimum set-up of the wind turbine gearboxes.

Comprehensive Testing

All wind turbine gearboxes are put through a spin test cycle at various speeds with careful monitoring of temperature and vibration levels in order to ensure that these large gearboxes are properly rebuilt before being put back into service at the top of the wind turbine tower.

Packaged & Ready

After successful test running the finished product is fastened to a specialized shipping stand and then shipped on special “air ride” low bed trailers in order to make sure that it arrives back at the wind farm in the same condition it leaves our plant.

Packaged & Ready

After successful test running the finished product is fastened to a specialized shipping stand and then shipped on special “air ride” low bed trailers in order to make sure that it arrives back at the wind farm in the same condition it leaves our plant.