Gearbox Inspection

With over 50 years of specialization, we've worked on virtually all types and styles of gearboxes. This experience helps us to quickly key in on critical areas and pinpoint where problems are initiating early in the inspection process. From there, we build a detailed report and make a plan to optimize future performance.

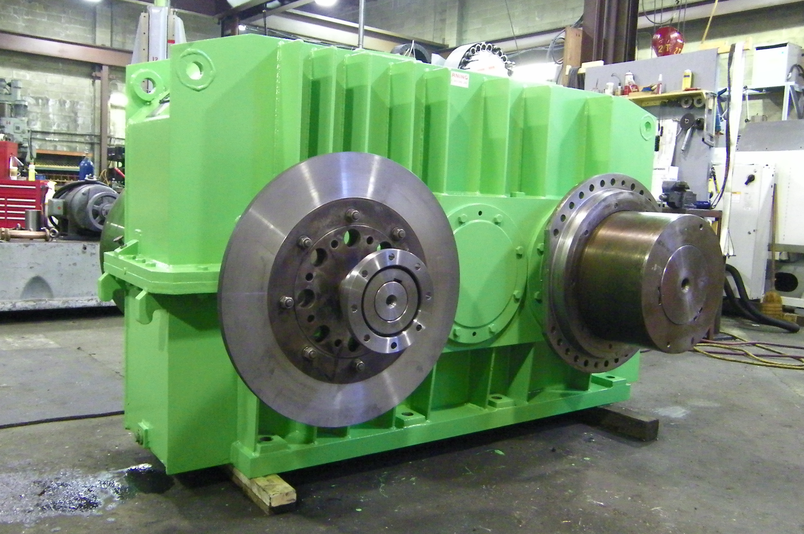

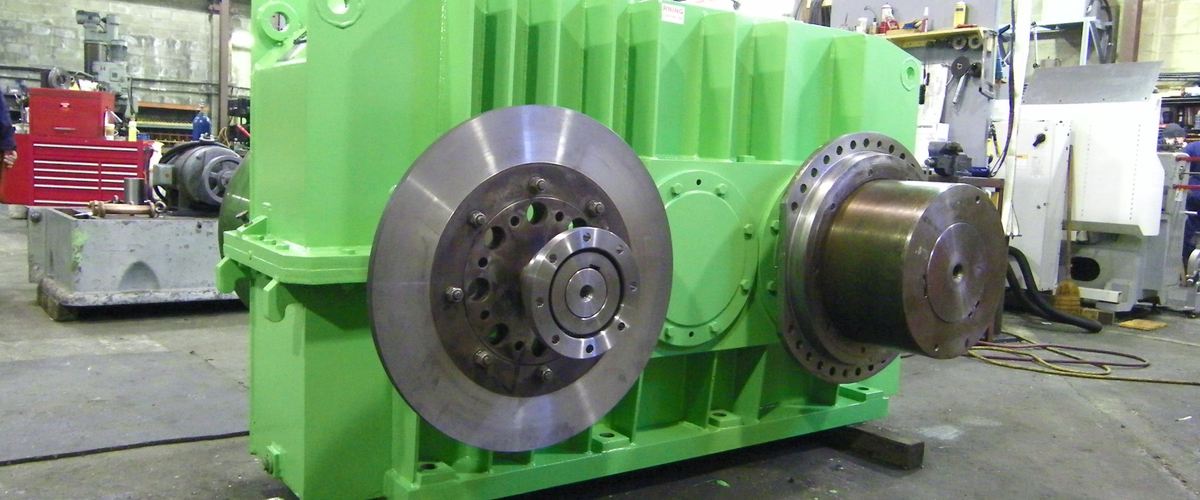

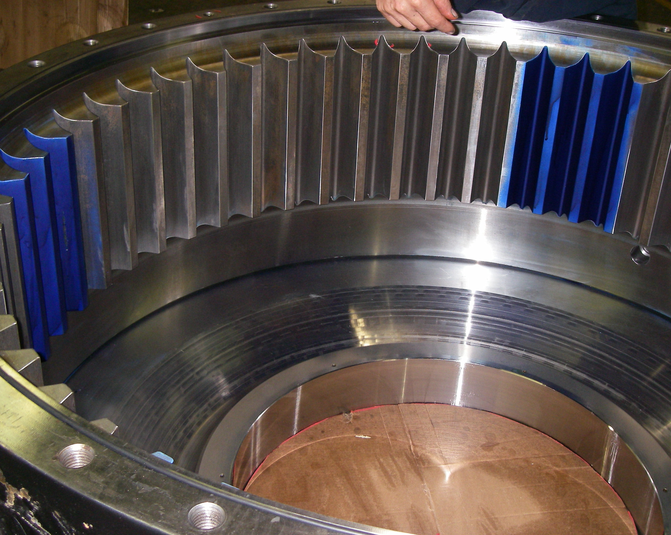

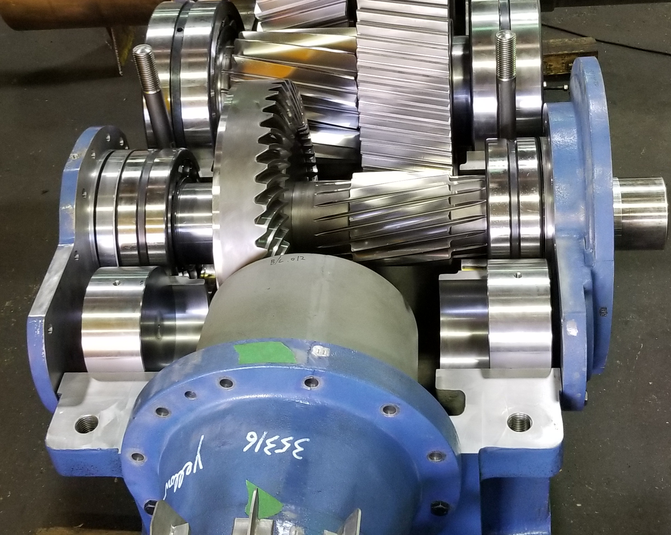

Gearbox Repair

Rebuilding is often more cost-effective than replacement, as many original components are generally re-usable. For savings, we build new components to suit the geometry of the reusable parts rather than replacing the entire gear train. This also avoids the cost of changing mounting arrangements, as many modern gearboxes have a more compact footprint which would require a transition base.

Gearbox Improvement

By determining the root cause of failure, we can improve the quality and geometry of internal components. For example, we often upgrade material from a casting to forged material as the steel is generally cleaner, resulting in a stronger more durable component. Knowing the details assists us in properly setting bearing clearances and gearing backlash to maximize the performance of the gearbox.

Gearbox Experience

All transmission rebuilds are the product of an in-depth reverse engineering process and collaboration with end users, which allows our experienced staff to identify the unique wear patterns and OEM weaknesses. With the focus on continual improvement, we can provide added confidence in extending component life, shortening rebuild time, and improving operating costs.

Gearbox Process

Gearbox Process

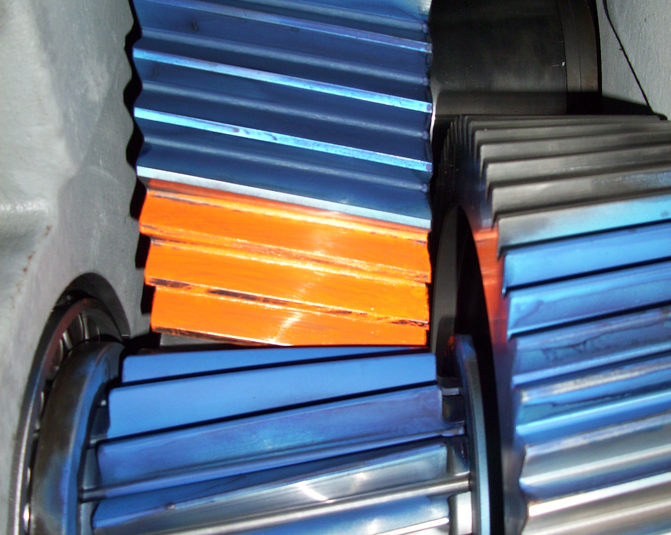

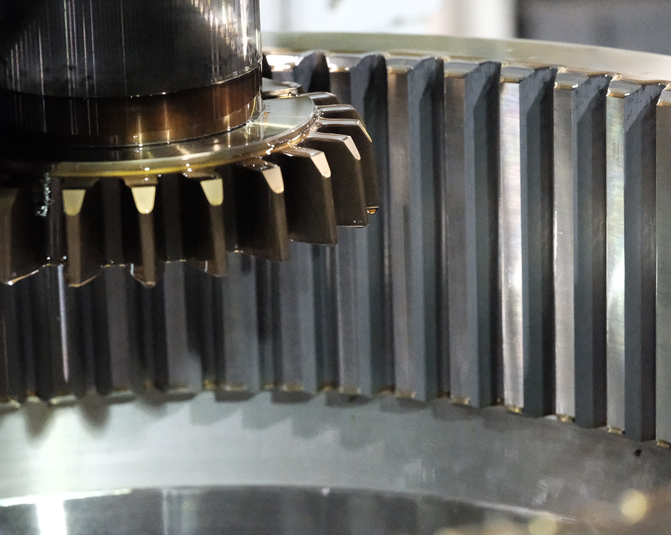

Gear Cutting & Grinding

Our highly trained operators cut and/or grind new gears on specialized equipment. Our operators, in conjunction with the engineering group, are skilled in optimizing gear geometry in order to provide improved overall performance of the rebuilt gearbox. We always provide new components which marry with existing components and are specifically designed for actual operating conditions.

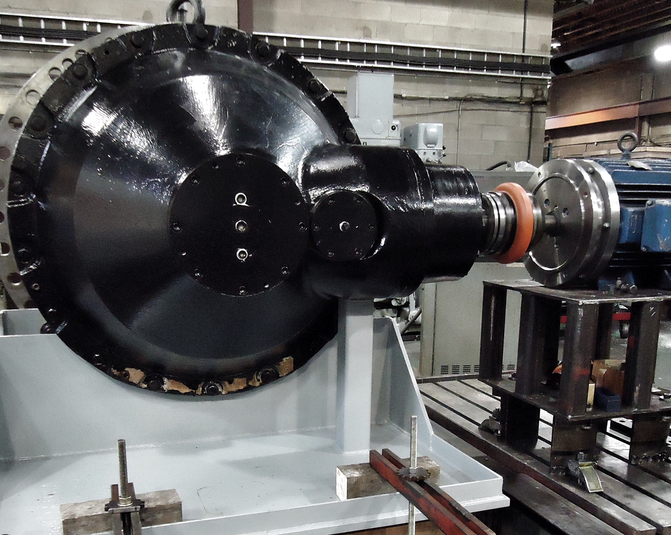

Gearbox Testing

All gearboxes are tested on our dedicated test stand where we can simulate real operating conditions with limited load testing in some cases. All gearboxes are spun tested in the customer’s primary direction of operation, and in a reversing direction if that is the case in operation. Full baseline vibration analysis and thermal imaging reports can be provided if desired.

Gearbox Brands Serviced

- Brevini

- Bonfiglioli

- David Brown

- Demag

- Dodge

- Dominion

- Eurodrive

- Falk

- Flender

- Foote-Jones

- Forano

- Hamilton

- Hansen

- Horsburgh & Scott

- Link Belt

- Lohmann & Stolterfoht (L&S)

- Nord

- Philadelphia

- Radicon

- Rexnord

- Rossi

- Santasalo

- Sumitomo

- Thyssen

- US Motors

- Western

- Winsmith

Commitment to Quality

We follow strict AGMA standards in all aspects of our manufacturing process and our Quality Management System complies with the requirements of ISO 9001:2015.

Commitment to Quality

We follow strict AGMA standards in all aspects of our manufacturing process and our Quality Management System complies with the requirements of ISO 9001:2015.